Explore mini split systems, factors influencing installation labor costs, DIY vs professional installation, and tips to minimize expenses in this comprehensive guide.When considering the installation of a mini split system for your home, understanding the associated labor costs is crucial for budgeting purposes. Mini split systems offer energy efficiency and flexibility, but the installation process can vary in complexity and expense. In this blog post, we’ll explore the intricacies of mini split systems, highlighting key factors that influence labor costs. We’ll provide insights on estimating those costs and weigh the pros and cons of DIY versus professional installation. Lastly, we’ll share valuable tips to help you minimize installation expenses without compromising on quality. Whether you’re looking to enhance your home’s comfort or reduce energy bills, this guide will equip you with the knowledge needed to make informed decisions about mini split installation.

Understanding Mini Split Systems

Mini split systems have gained popularity in recent years as an efficient heating and cooling solution for homes and offices. Unlike traditional HVAC systems, mini splits operate without ductwork, which makes them an attractive option for retrofitting older buildings or creating climate control in specific zones.

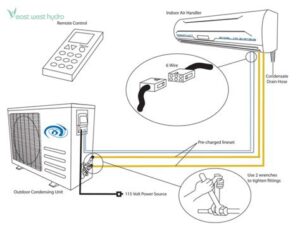

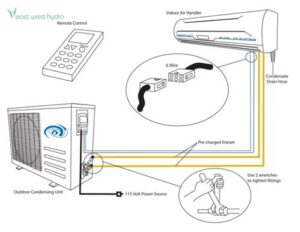

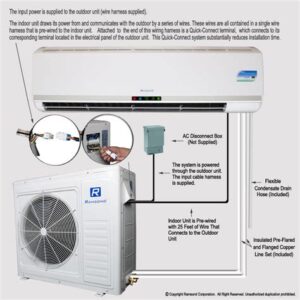

A mini split system consists of two main components: an outdoor compressor and one or more indoor air-handling units. These units work together to regulate indoor temperatures effectively. The indoor units can be wall-mounted, ceiling-mounted, or even floor-mounted, giving homeowners flexibility in terms of placement and style.

The energy efficiency of mini split systems is another crucial factor driving their popularity. They typically have a higher SEER (Seasonal Energy Efficiency Ratio) compared to traditional systems, which means they use less energy to produce the same cooling effect. This efficiency can lead to significant savings on energy bills over time.

| Component | Function |

|---|---|

| Outdoor Unit | Contains the compressor and condenser; responsible for heat exchange |

| Indoor Unit | Distributes conditioned air into the living space |

A major benefit of mini split systems is their zoning capability, allowing users to heat or cool specific areas independently. This feature is beneficial for homes with varying needs across different rooms, delivering c

Factors Affecting Installation Labor Cost

When considering the installation labor cost for mini split systems, several key factors come into play. Understanding these factors can help homeowners and contractors alike to plan their budgets more effectively.

1. Complexity of the Installation: Installation complexity is one of the primary drivers of labor costs. If the installation site requires extensive modifications, such as electrical work, ductwork adjustments, or structural alterations, the labor cost will typically increase. Systems that require more intricate setups will demand more technician time and expertise, leading to higher costs.

2. Location: Geographic location can significantly influence installation labor costs. Areas with a higher cost of living often see increased rates for skilled labor. Additionally, if the installation site is in a remote or hard-to-access location, technicians may charge extra for travel and logistics, thereby affecting overall expenses.

3. Brand and Unit Size: The brand of the mini split system and its size also play a role in determining installation labor costs. Premium brands typically come with higher installation fees, while larger units may require extra manpower and time to install. Therefore, when budgeting for a mini split system, it’s essential to consider not just the equipment costs, but also how these factors will influence labor.

By taking these factors into account, homeowners can better anticipate the labor costs associated with installing a mini split system, allowing for more accurate budget planning and minimizing unexpected expenses.

Estimating Labor Cost for Installation

When considering the installation of mini split systems, one of the crucial aspects to evaluate is the labor cost associated with the process. This cost can vary significantly based on a variety of factors, including geographical location, complexity of the installation, and whether additional components are required.

The average labor cost for installing a mini split system typically ranges from $500 to $2,000. However, this can fluctuate based on specific local market conditions. For instance, hiring an HVAC contractor in metropolitan areas may be more expensive compared to rural locations. Below is a breakdown of some key factors that can influence the labor cost:

| Factor | Impact on Cost |

|---|---|

| Location | Higher labor costs in urban areas due to demand. |

| System Complexity | More complex installations will increase labor hours. |

| Additional Components | Adding accessories can drive up labor costs. |

| Contractor Experience | Experienced contractors may charge higher rates. |

Moreover, estimating labor costs accurately requires a thorough assessment of your specific installation requirements. While obtaining quotes from various contractors, always ensure you understand the scope of work included in the overall cost. Clear communication about what exactly will be installed can help prevent any unexpected changes to the labor cost as the project progresses.

Comparing DIY vs Professional Installation

When considering a mini split installation, many homeowners face the dilemma of whether to attempt a DIY installation or hire a professional. Both options have their advantages and disadvantages, making it essential to weigh the factors involved before making a decision.

DIY installation can save you a significant amount of money on labor costs. This option is appealing for those who enjoy hands-on projects and have a basic understanding of home ventilation systems. However, there are several risks associated with taking this route:

- Potential for improper installation, leading to inefficiency.

- Risk of damaging the unit or home.

- Time-consuming process that may take longer than expected.

On the other hand, hiring a professional installer ensures that the job is done correctly and efficiently. Professionals come with experience and knowledge, which minimizes the chance of errors. The benefits of this option include:

- Guaranteed compliance with local building codes.

- Access to warranties and service contracts.

- Expert troubleshooting and advice for future maintenance.

Ultimately, the decision between DIY and professional installation of a mini split system should be based on your skill level, budget, and willingness to tackle potential complications. While going the DIY route may offer immediate savings, the long-term benefits of hiring a professional can outweigh the initial installation labor costs.

Tips for Minimizing Installation Labor Cost

Installing a mini-split system can be a significant investment, and understanding how to minimize installation labor costs can help you save money while ensuring a quality setup. Below are some practical tips you can consider when planning your installation.

1. Research Multiple Contractors: Get quotes from different contractors to compare costs. This will not only give you a sense of the average labor rates in your area but also help you find reputable professionals willing to work for competitive prices.

2. Schedule During Off-Peak Seasons: Labor rates can vary significantly based on the season. If possible, try to schedule your installation in the off-peak seasons (like late fall or winter). During these times, many contractors may offer discounted rates as demand is lower.

3. Bundle Services: If you’re planning to install additional systems or make repairs, consider bundling services with your mini-split installation. Many contractors offer discounts when multiple jobs are done simultaneously.

4. DIY Preparation: While hiring a professional is often necessary for the installation itself, you can prepare your space by clearing out any obstructions or making minor adjustments that will save time. This can effectively reduce the overall labor costs.

5. Take Advantage of Promotions: Keep an eye out for promotional offers or rebates that might be available for energy-efficient systems. Some manufacturers and local energy companies offer financial incentives that can reduce your overall installation costs.

By employing these tips, you can effectively minimize your installation labor cost and ensure a smooth, efficient installation process for your mini-split system.

Frequently Asked Questions

What factors influence the labor cost of mini split installation?

Several factors influence the labor cost, including the complexity of the installation, the type of mini split system being installed, local labor rates, and the experience level of the technician.

How much can I expect to pay for labor on mini split installation?

Labor costs for mini split installation typically range from $500 to $2,000, depending on the factors mentioned earlier and your geographical location.

Are there any additional costs to consider besides labor when installing a mini split?

Yes, additional costs may include materials, permits, and any possible electrical upgrades that might be necessary for the installation of the mini split system.

Can I install a mini split system myself to save on labor costs?

While it’s possible to install a mini split system yourself, it requires specialized knowledge and tools. Improper installation can void the warranty and lead to inefficiency, so hiring a professional is generally recommended.

How long does it typically take to install a mini split system?

The installation process for a mini split system usually takes between 4 to 8 hours, depending on the complexity of the job.

What should I look for when hiring a contractor for mini split installation?

When hiring a contractor, look for their experience, references, and customer reviews. It’s also important to verify their licenses, insurance, and any warranties they offer on their work.

Does the location of the mini split unit affect installation costs?

Yes, the location can significantly affect installation costs. More difficult locations, such as those that require extensive electrical work or additional piping, can increase labor costs.