Explore factors influencing mini split installation costs, including system types, labor vs. DIY, required materials, and cost comparisons with traditional HVAC systems.When considering the installation of mini-split systems, understanding the associated costs can be a complex endeavor. These systems offer a flexible and efficient heating and cooling solution, but the price to install them can vary widely based on numerous factors. From the type of mini-split system you choose to the labor costs involved, each element contributes to the overall expense. This blog will delve into the various components that affect installation costs, compare mini-split systems with traditional HVAC solutions, and explore the pros and cons of DIY installation versus hiring professionals. Whether you’re looking to add comfort to your home or improve energy efficiency, knowing the cost implications will help you make an informed decision about your cooling and heating needs.

Factors affecting installation cost

When considering the cost to install mini splits, various factors can influence the final price. Understanding these can help you make an informed decision and potentially save on installation expenses. Below are some key factors that affect the overall installation cost:

- Size of the System: The size and capacity of the mini split system are primary determinants of installation cost. Larger systems that can cool or heat more area generally come with higher installation costs.

- Type of Installation: Whether you choose a single-zone or multi-zone system will affect costs. Multi-zone systems typically require more labor and materials.

- Location: The complexity of the installation site plays a significant role. For instance, installation in a hard-to-reach area or a multi-story building may require additional labor and equipment.

- Local Labor Rates: Labor costs can vary widely depending on the geographical location. Urban areas may have higher hourly rates compared to rural regions.

- Permits and Regulations: Some regions may require permits for HVAC installations, adding to the cost. It’s essential to check local regulations.

- Type of Wall and Ceilings: The condition of your walls and ceilings can also affect installation complexity. For example, installing units in masonry or concrete walls can require special tools and techniques.

Additionally, consider that the cost to install mini splits can fluctuate based on seasonal demand. During peak seasons, when demand is high, prices may increase. Furthermore, promotions or discounts might be available at certain times of the year, impacting your potential installation costs.

Understanding these factors can help you gauge the overall cost to install mini splits, allowing for better budgeting and decision-making. Always get multiple quotes from licensed professionals to ensure you are receiving a fair price for the installation service.

In summary, the installation cost of mini splits can vary significantly based on several elements, and being aware of these can empowe

Mini split system types

When considering a mini split system, it’s essential to understand the various types available. Each type has its unique features, efficiency levels, and installation requirements, making it crucial to choose one that fits your specific needs.

Here are the main types of mini split systems you may encounter:

- Single Zone Systems: Designed to cool or heat a single room or zone, these systems are perfect for smaller spaces or individual comfort needs.

- Multi Zone Systems: These can service multiple rooms or zones with a single outdoor unit connected to multiple indoor units. They are ideal for larger properties where different areas require different temperature settings.

- Concealed Duct Mini Splits: These are built into ceilings or walls to provide unobtrusive cooling and heating. They work well in homes where aesthetics are a concern.

- Wall-Mounted Systems: Commonly installed high on walls, these systems are popular due to their effectiveness and ease of installation. They offer flexibility in positioning and can fit various décor styles.

- Ceiling-Mounted Systems: These units are hung from the ceiling, ideal for spaces with limited wall space, providing an even distribution of air.

Understanding these mini split system types can help you select the right option for your home or office. Be sure to consider factors such as energy efficiency, aesthetics, and the layout of the space when making your decision.

Labor costs vs. DIY installation

When considering the cost to install mini splits, understanding the differences between hiring professional labor and opting for a DIY installation is crucial. Each method has its advantages and potential pitfalls, which can significantly impact your overall expenses.

Hiring a professional service typically entails higher upfront costs due to labor rates. Professional installation can range from $500 to $2,000 depending on your location and the complexity of the installation. This fee ensures that the system is installed correctly, adhering to local codes and manufacturer guidelines.

On the other hand, a DIY approach can save you significant money. However, it’s important to weigh the potential costs associated with mistakes. If improperly installed, a mini split system can lead to ineffiency, increased utility costs, and even damage to the equipment. Moreover, without proper knowledge, you may end up needing to call in a professional later on, negating your initial savings.

In the end, the choice between professional labor and a DIY project hinges on your experience, confidence in handling electrical and HVAC systems, and the potential for additional costs due to errors.

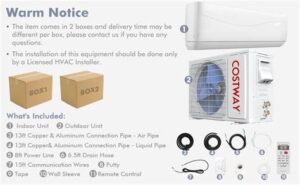

Additional materials needed

When it comes to installing a mini-split system, there are several additional materials that you may need to consider. These materials can significantly affect the overall installation cost and must be factored in before you begin the process. Below is a detailed list of the common materials required for a successful mini-split installation:

- Line Set – This includes insulated copper tubing for refrigerant lines and drain lines.

- Electrical Wiring – Adequate wiring is necessary to connect your outdoor and indoor units to the power supply.

- Mounting Brackets – Essential for securely attaching the indoor and outdoor units to walls and platforms.

- Vibration Dampeners – Helps to minimize noise from the compressor unit outdoors.

- Insulation – Used for refrigerant lines to prevent energy loss.

Each of these items not only contributes to the functionality of the mini-split system but also impacts the total cost involved in the installation. It’s essential to evaluate these materials’ costs upfront to better manage your budget.

Moreover, purchasing the right additional materials can ensure a smoother installation process. If you’re opting for a DIY installation, having these materials on hand will save you time and potential headaches down the line.

Ultimately, understanding the additional materials needed for your mini-split installation will enhance your overall experience and hel

Comparing installation costs to traditional HVAC

When considering the cost to install mini splits, it’s crucial to compare these expenses to those associated with traditional HVAC systems. The upfront investment, installation process, and long-term operational costs can significantly differ, making it essential to understand these factors.

| Cost Factors | Mini Split Systems | Traditional HVAC Systems |

|---|---|---|

| Initial Installation Cost | $$$ | $$$$ |

| Labor Costs | Lower | Higher |

| Energy Efficiency | High | Medium |

| Maintenance Expenses | Lower | Higher |

Initial installation costs for mini splits are generally lower than those for traditional HVAC systems. This is largely due to the less extensive work required, such as minimal ductwork, which can drive up the costs in conventional setups.

Furthermore, with mini splits, the labor costs are usually reduced, as the installation can often be completed in a shorter timeframe. Comparatively, traditional HVAC systems often require more complex installations, leading to higher labor expenses.

Another advantage of mini splits is their energy efficiency. These systems run on less energy than traditional units, resulting in long-term savings that can offset the initial installation costs. In contrast, traditional HVAC systems tend t

Frequently Asked Questions

What are mini splits?

Mini splits, or ductless mini-split systems, are heating and cooling systems that consist of an outdoor compressor unit and one or more indoor air handlers.

What factors influence the cost of installing mini splits?

The cost can vary based on factors like the brand of the mini split, the number of indoor units needed, installation complexity, and local labor rates.

What is the average cost to install a mini split system?

On average, the total cost to install a mini split system ranges from $3,000 to $5,000, including equipment and installation.

Are there any additional costs associated with installing mini splits?

Yes, additional costs may include electrical upgrades, ductwork modifications, permits, and potential repairs to existing HVAC systems.

Can I install a mini split system myself?

While it’s possible to install a mini split system as a DIY project, it is highly recommended to hire a professional for proper installation, as it involves refrigerant handling and electrical work.

What are the potential energy savings from using mini splits?

Mini splits are known for their energy efficiency, potentially providing savings of 30% or more on energy bills compared to traditional HVAC systems.

How long do mini splits last?

With proper maintenance, mini split systems can last between 15 to 20 years, making them a good long-term investment for heating and cooling.